When it comes to selecting the right metal for your project, understanding the differences between mild steel vs stainless steel can make a big impact on quality, cost, and performance. Both are widely used in industries like construction, automotive, furniture manufacturing, and industrial fabrication. However, each type of steel has unique characteristics that make it suitable for specific purposes.

This article provides a complete metal comparison that helps you understand the properties, advantages, and limitations of both materials. Whether you’re a manufacturer, engineer, or buyer, this guide will help you make an informed decision using practical fabrication guides and expert insights.

1- What Is Mild Steel?

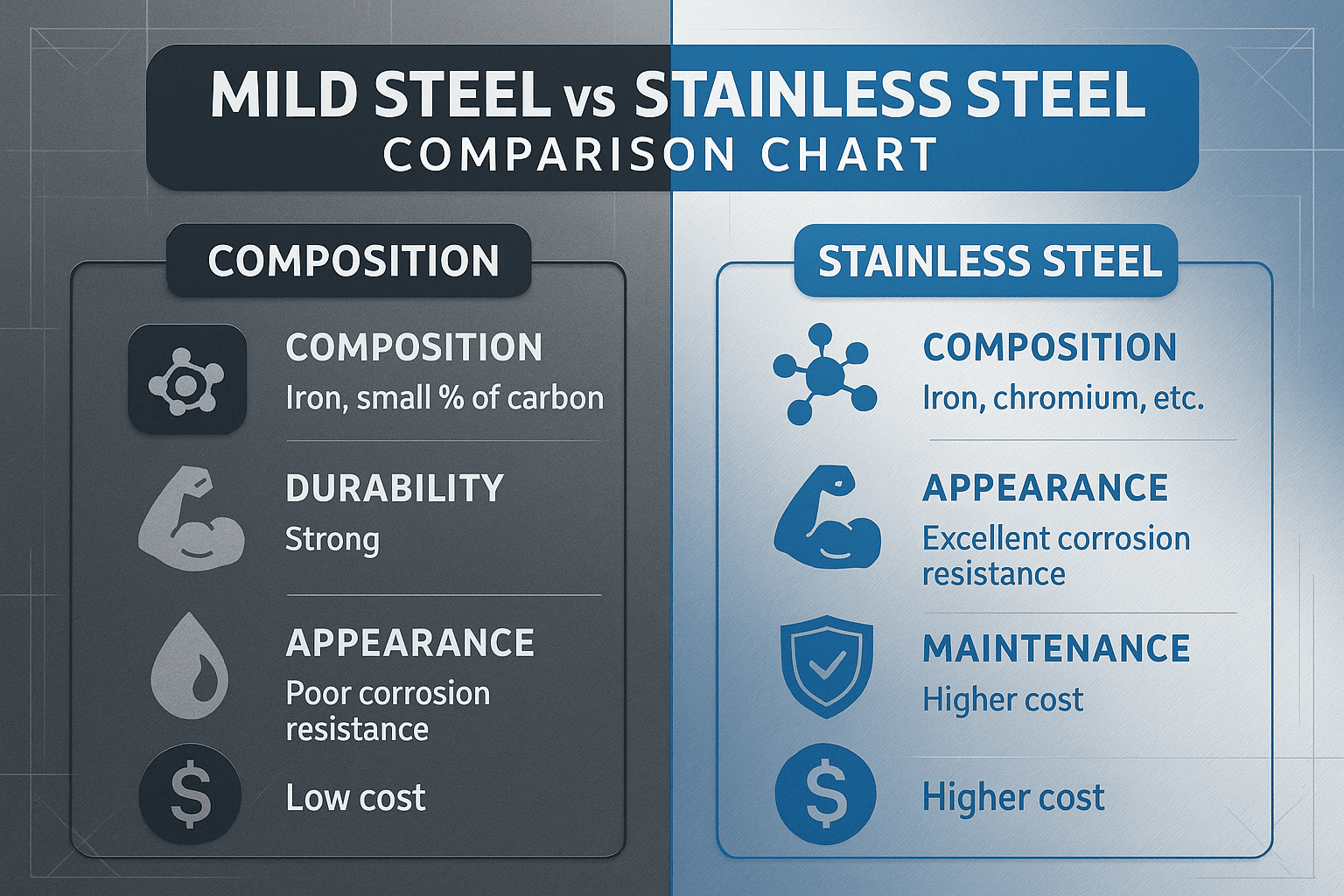

Mild steel, also known as low-carbon steel, contains a small percentage of carbon (typically 0.05% to 0.25%). It’s one of the most commonly used materials in metal fabrication because it is affordable, easy to work with, and versatile.

Key Properties of Mild Steel:

- Ductile and Malleable: It can be easily bent, cut, and shaped without cracking.

- Weldable: Excellent for welding and machining applications.

- Cost-Effective: Much cheaper compared to other metals.

- Magnetic: It can be magnetized, making it useful in electrical applications.

Common Uses:

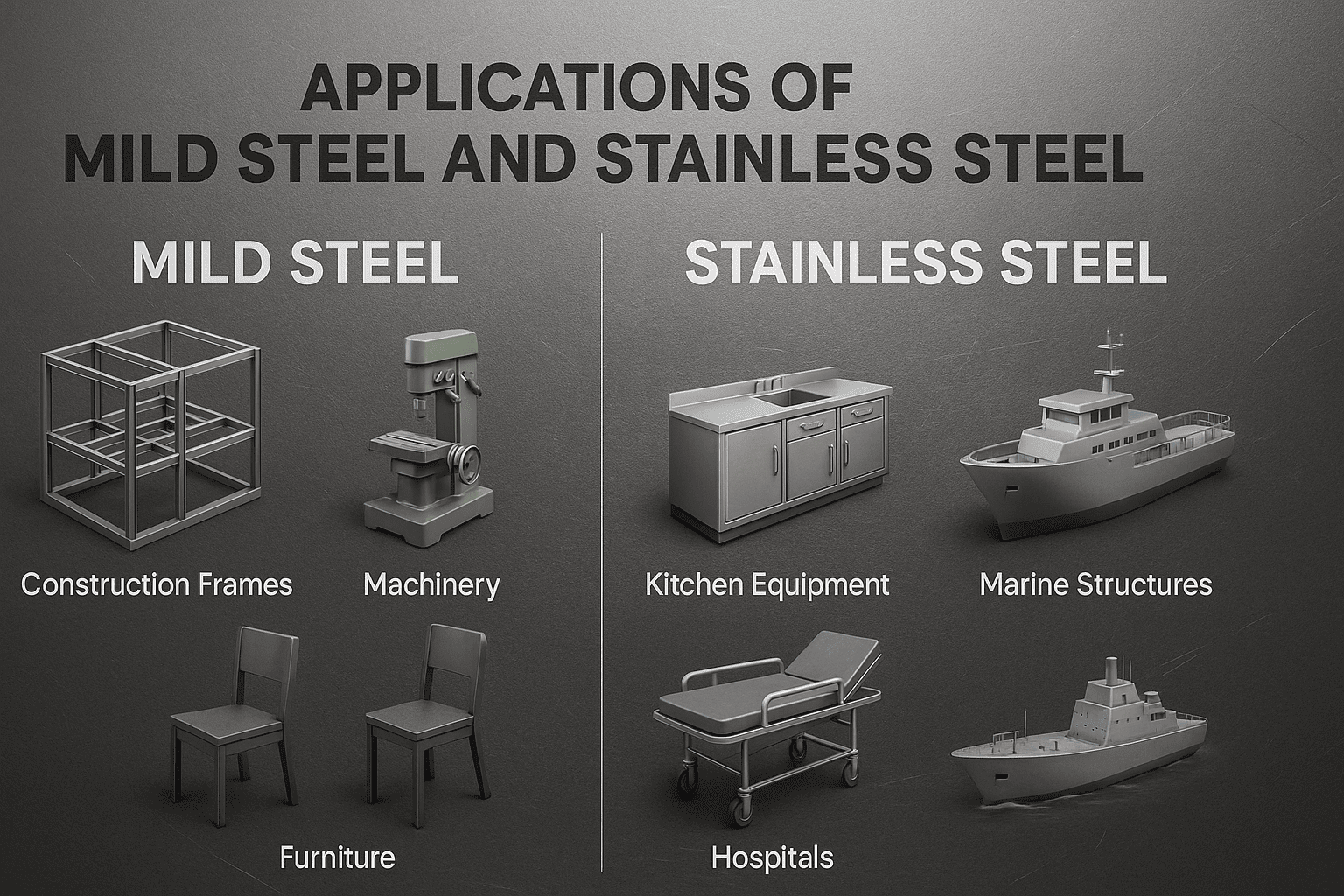

Mild steel is often used in the construction of steel frames, pipelines, vehicle parts, and furniture. It’s also the backbone material for industrial machinery and structural applications where corrosion resistance isn’t the top priority.

2- What Is Stainless Steel?

Stainless steel is an alloy made primarily of iron, chromium (at least 10.5%), and other elements like nickel and molybdenum. The chromium forms a thin, invisible oxide layer on the surface that prevents rust and corrosion, giving stainless steel its signature shine and durability.

Key Properties of Stainless Steel:

- Corrosion Resistant: Ideal for humid, coastal, or chemical environments.

- Aesthetic Appeal: Shiny and modern look, perfect for architectural designs.

- Hygienic Surface: Resistant to bacterial growth, suitable for medical and food-grade applications.

- High Strength: Retains strength even at high temperatures.

Common Uses:

Stainless steel is widely used in kitchen equipment, chemical plants, medical instruments, marine hardware, and decorative projects that require long-lasting shine and corrosion protection.

3- Key Differences Between Mild Steel and Stainless Steel

Let’s break down the major differences to simplify your metal comparison:

| Feature | Mild Steel | Stainless Steel |

| Composition | Iron + 0.05–0.25% Carbon | Iron + ≥10.5% Chromium + Nickel |

| Corrosion Resistance | Low | Excellent |

| Appearance | Dull, gray finish | Bright, shiny finish |

| Strength | Moderate | High tensile strength |

| Cost | Low | High |

| Maintenance | Requires painting or coating | Low maintenance |

| Magnetic | Yes | Usually non-magnetic (depending on grade) |

| Applications | Construction, automotive, machinery | Kitchens, hospitals, marine, decorative |

This fabrication guide comparison shows that mild steel is more practical for budget-sensitive and structural applications, while stainless steel excels in environments where aesthetics, hygiene, or corrosion resistance are essential.

4- Advantages of Mild Steel

- Affordability: One of the biggest advantages of mild steel is its low cost, making it ideal for large-scale industrial use.

- Ease of Fabrication: It can be easily cut, drilled, and welded, offering flexibility in design.

- Availability: Mild steel is readily available in various forms like sheets, rods, and bars.

- Repairability: Damaged sections can be easily repaired through simple welding methods.

However, it’s important to note that mild steel is not corrosion-resistant. Without protective coatings like paint or galvanization, it can rust when exposed to moisture or harsh environments.

5- Advantages of Stainless Steel

- Corrosion Resistance: Its chromium content makes it naturally resistant to rust and corrosion.

- Low Maintenance: Stainless steel does not need painting or surface treatment.

- Hygienic Surface: Smooth finish makes it easy to clean and maintain, which is why it’s used in hospitals and food industries.

- Aesthetic Value: Shiny, modern appearance enhances product appeal.

- Durability: Long-lasting and resistant to wear and tear, making it cost-effective over time.

Despite its higher price, stainless steel’s long life and minimal maintenance often balance out the initial investment.

6- Which Metal Is Easier to Fabricate?

When comparing mild steel vs stainless steel for fabrication, mild steel usually wins in terms of workability. It can be bent, welded, and machined with less specialized equipment. Stainless steel, on the other hand, is harder and may require specific tools or high-grade welding techniques to maintain its corrosion resistance and appearance.

If your project involves custom shapes or frequent modifications, mild steel provides more flexibility. But if the final product needs to withstand exposure to moisture or chemicals, stainless steel is the better option.

7- Cost Considerations

Price is often the deciding factor in a metal comparison. Mild steel is cheaper both in raw material and processing costs. Stainless steel costs more due to alloying elements like chromium and nickel, and also requires more precise handling.

However, the real cost must be evaluated based on lifespan and maintenance. Mild steel may require painting, coating, or replacements over time, while stainless steel offers a longer lifespan with minimal maintenance needs.

8- Sustainability and Environmental Impact

Stainless steel is 100% recyclable without losing quality, which makes it environmentally friendly. It’s also energy-efficient in production compared to some coated steels. Mild steel is also recyclable, but it may require additional processing to remove paint or coatings before reuse.

From a sustainability standpoint, stainless steel is often preferred for long-term and eco-friendly projects.

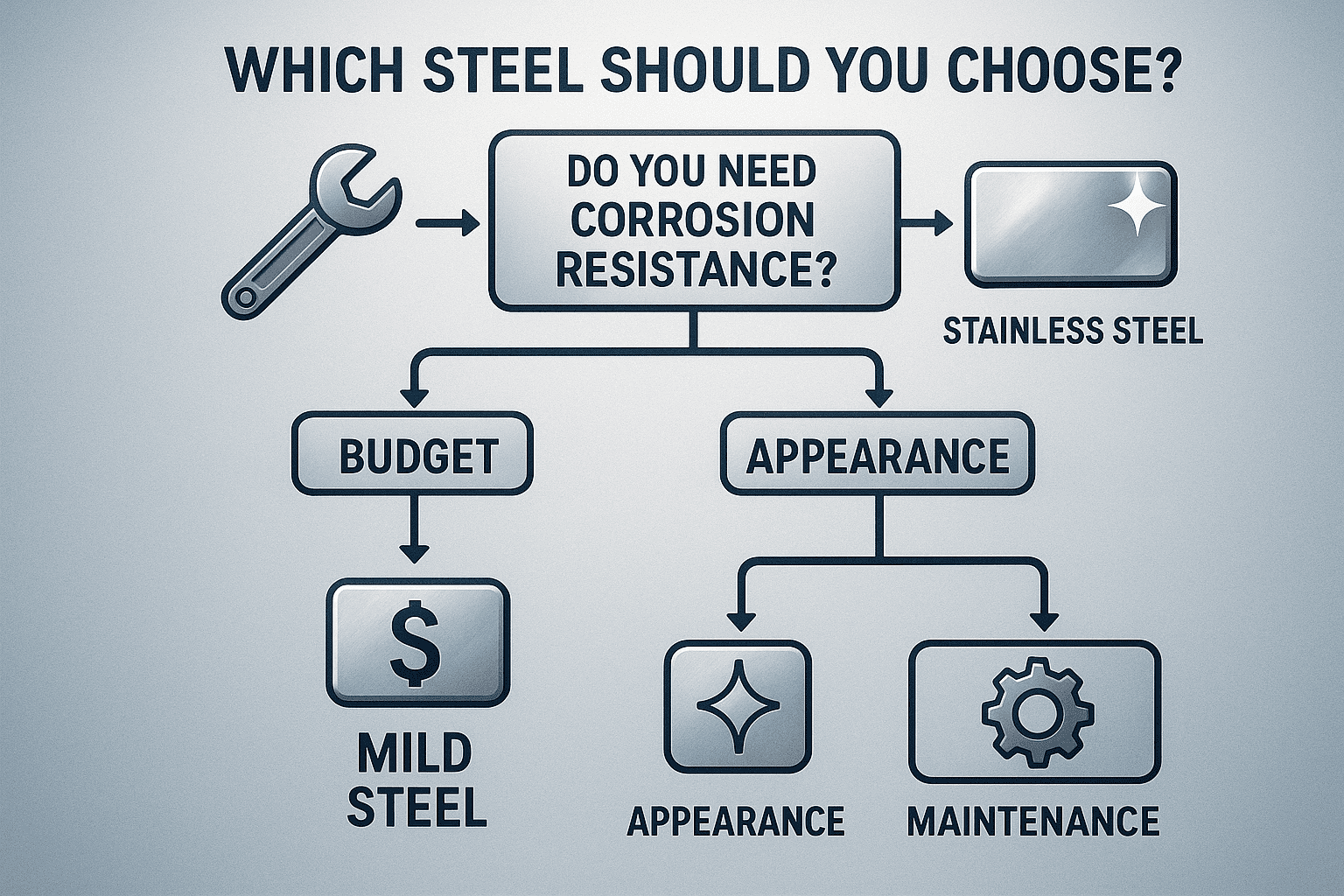

9- Choosing the Right Steel for Your Needs

Use this fabrication guide to help you decide:

- Choose Mild Steel If:

- You’re working on a budget.

- The project is indoors or away from moisture.

- You need flexibility in cutting, welding, and shaping.

- Choose Stainless Steel If:

- The product will face water, chemicals, or outdoor exposure.

- You require a premium appearance.

- You want long-term durability and low maintenance.

10 – Final Thoughts

Both mild steel and stainless steel are valuable materials with their own advantages. The best choice depends on your specific needs — cost, durability, environment, and design preferences.

If you’re looking for strength and affordability, mild steel is your go-to option. But if you want durability, corrosion resistance, and elegance, stainless steel will serve you better in the long run.

Understanding the balance between mild steel vs stainless steel is the key to achieving the right mix of performance, cost, and quality in any project. With the right knowledge from this metal comparison and smart planning through fabrication guides, you can confidently choose the metal that perfectly fits your project’s goals.